Share Post:

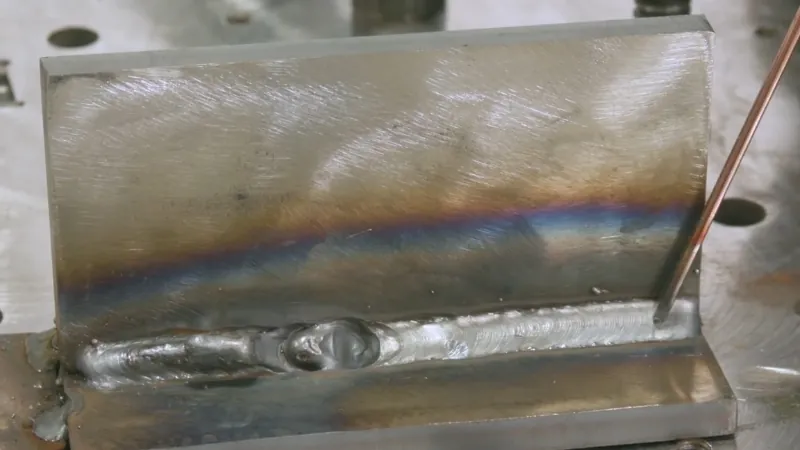

Welding might look like sparks and fire to the untrained eye, but anyone who’s worked with frames, whether on a vehicle chassis, structural machine housing, or aerospace skeleton, knows it’s all about precision.

A little too much heat here, the wrong arc settings there, and over time, the frame that once looked solid and clean can start to sag, crack, or just… soften.

At the heart of this problem lies one of the most misunderstood aspects of modern MIG welding: pulse settings. When configured right, pulse MIG is a gift. It gives you cleaner welds, less spatter, and better control, especially on materials like aluminum or stainless.

But if the settings are even slightly off, the long-term consequences can be severe, especially when it comes to frame softening.

Let’s walk through what’s really happening under the hood and how to keep your welds tight, strong, and built to last.

Table of Contents

ToggleWhat Is MIG Pulse Welding and Why It Matters for Frames

MIG pulse welding, or GMAW-P, isn’t your basic wire-feed MIG setup. It alternates between a high peak current and a lower background current, cycling rapidly, anywhere from 0.5 Hz to over 500 Hz on industrial machines.

That alternating rhythm does more than just sound fancy:

- It controls heat input, helping avoid burn-through and distortion.

- It improves bead appearance and reduces post-weld cleanup.

- It makes welding high-strength or heat-sensitive materials more manageable.

That last part is why it’s often used for structural frames. Frames made from materials like 6061-T6 aluminum or high-strength steel don’t play well with excess heat.

So, welders lean on pulse MIG to stay within safe temperature zones while getting strong, reliable welds.

But if you mismanage the pulse settings, you don’t get those benefits. You get heat. Too much of it. And that’s where the trouble starts.

Pulse MIG is powerful, especially for frames, so if you suspect any distortion, bring it to a certified auto repair shop.

The Heat Factor & Why Frames Are So Sensitive

Let’s talk about heat input for a second. Welding always involves heat, but when it comes to frames, the key is not just how much heat you add, but how fast, where, and for how long. In pulse MIG, several dials control this:

- Peak Current – delivers the punch to push metal droplets across the arc.

- Background Current – keeps the arc alive between pulses.

- Pulse Frequency – determines how often current flips between high and low.

- Pulse Balance – controls how much time is spent in each current phase.

- Travel Speed – slower travel means more heat per inch of weld.

Now apply that to frame welding. Frames have to take repeated loads, vibrations, and, especially in vehicles, road abuse. When you overcook the material with poor settings, you alter the metal around the weld, also known as the Heat Affected Zone (HAZ).

In aluminum, for example, this heat can dissolve or coarsen tiny strengthening particles like Mg₂Si. Once that happens, the surrounding area becomes soft, and we’re not talking about a little softness.

In 6061-T6, strength loss in the HAZ can hit 30 to 40 percent. That’s like welding a high-strength frame and ending up with a soft aluminum soda can on the sides.

Real-World Frame Softening Triggers

Here’s where a lot of welders get into trouble. You set your machine based on experience, or you go with a chart on the side of the welder and figure “close enough.”

But with MIG pulse, especially on aluminum or thinner gauge steel, small mistakes can snowball fast.

1. Cranking Peak Current Too High

Say you’re working with 1/8″ aluminum and dial your peak current to 250 amps. Sure, you’ll get great penetration. But you’ll also put way too much heat into the area, especially if your travel speed isn’t fast enough to keep things moving.

2. Background Current Not Low Enough

Background current should chill things out between pulses. If it’s sitting too high, say at 70% of your peak, it’s not really giving the material a break. You’re running hot constantly, even when you think you’re “resting.”

3. Low Pulse Frequency

At 60 Hz or lower, your pulses are stretched out. That gives each high-current period more time to heat up the workpiece. On thin frames, you want more frequent, shorter bursts, usually 100 Hz or more, to keep temps in check.

4. Unbalanced Pulse Timing

A 70/30 split in favor of peak current sounds good if you’re trying to burn into thick steel. But on an aluminum bike frame or truck subframe, it’s a recipe for structural soft spots. A more neutral or background-heavy balance keeps the average heat lower.

What Long-Term Frame Softening Looks Like

It’s not always obvious right away. A freshly welded frame looks perfect on the surface. But give it a year or two, a few thousand miles, a season of machinery use, and things start showing up:

- Creep: Sections start bending slightly under constant loads.

- Cracks: Fatigue cracks appear, especially near weld toes.

- Sagging: Misalignment grows over time due to soft zones losing stiffness.

- Unexpected Breaks: Welds that looked good on day one just give out.

One mechanic shared a case where a truck chassis repair was done with a pulse MIG setup using stock settings.

Two years in, the frame had sagged so much that wheel alignment couldn’t be maintained. The weld hadn’t failed, but the surrounding HAZ had lost its strength.

Common Mistakes That Lead to Overheating

Mistake

Consequence

Peak Current Too High

Deep HAZ softening, burn-through

Background Current Too High

Cumulative overheating, wide HAZ

Low Pulse Frequency

Slower transitions, more time at peak heat

Incorrect Pulse Balance

Overexposure to peak current

Travel Speed Too Slow

Increased heat input per inch

Inadequate Gas Flow

Porosity, poor arc stability

Wrong Shielding Gas

Excess oxidation, inconsistent arc behavior

Aluminum vs. Steel Frames

Aluminum (e.g., 6061-T6)

- Most sensitive to overheating

- Strength comes from precipitation hardening

- Once precipitates dissolve or coarsen, strength drops fast

- Often requires re-aging after welding

High-Strength Steel

- Better at tolerating heat, but still prone to distortion and softening

- Pulse MIG helps avoid over-penetration on thinner parts

- More forgiving with post-weld strength, but harder to reshape once softened

How to Prevent Frame Softening

@welddotcomIf you are trying to MIG weld aluminum you have a few options. First you can get away with running it around 10 feet using a teflon liner. Another option is using a spool gun or if you want to big rolls of wire use a push pull gun like this Freedom Drive from Abicor Binzel, which will help keep the wire tight through the MIG gun over long distances because of the drive rollers pulling the wire as well as the machine pushing the wire. Watch the full video showing different ways Not to MIG weld aluminum on YouTube https://foxly.link/Iv6p90 #mig #migwelding #aluminum #spoolgun #pushpull #abicorbinzel #freedomdrive #welding #welddotcom

You don’t need magic. You need discipline, the right equipment, and settings that actually match your material and thickness.

1. Tune Pulse Settings Intelligently

For 1/8” 6061 aluminum:

- Peak Current: 150–200 amps

- Background Current: 30–50% of peak

- Pulse Frequency: 100–150 Hz

- Pulse Balance: 50–60% background time

These numbers aren’t universal, but they give a solid baseline for heat-sensitive frame materials.

2. Use the Right Gas and Flow Rate

- Aluminum: 100% argon at 25–40 CFH

- Steel: 75% argon / 25% CO₂ blend

Always double-check your nozzle and shielding. Porosity from bad gas flow often looks like a heat issue and gets misdiagnosed.

3. Re-Age Welded Aluminum

After welding, especially on 6061, consider a re-aging treatment if the frame is critical. Heating to around 320°F for several hours can restore up to 90% of the lost strength.

If that’s not feasible, reinforce the weld area or use thicker stock near the joints.

4. Follow Manufacturer Specs

Use a Welding Procedure Specification (WPS) when you can. Check the filler metal data sheet. Most of the big players like Miller, Lincoln, or Hobart publish settings for every material and wire size combo.

5. Go Synergic

If you’ve got a modern welder with synergic controls, use them. These machines automatically adjust wire feed and voltage when you set your amperage and material type. They’re not perfect, but they take a lot of guesswork out of pulse tuning.

Welding 6061-T6 (1/8”)

Parameter

Recommended Setting

Why It Matters

Peak Current

150–200 amps

Balance between fusion and heat control

Background Current

30–50% of peak

Keeps arc alive without overheating

Pulse Frequency

100–150 Hz

Reduces peak time, minimizes HAZ growth

Pulse Balance

50–60% background time

Helps control cumulative heat input

Shielding Gas

100% Argon @ 25–40 CFH

Clean arc and solid bead profile

Wire Diameter

0.035” (0.9 mm)

Smooth transfer with manageable feed rate

Where It Matters Most

- Automotive: Soft welds on a unibody car mean crash crumple zones start where you don’t want them.

- Aerospace: Even slight softening can halve fatigue life in aluminum spars and beams.

- Industrial Equipment: Frames lose rigidity, causing alignment issues or vibration problems.

Welding a frame isn’t just joining metal; it’s shaping how that structure holds up under years of use. If you’re torching your materials with the wrong pulse settings, you’re setting up a failure no one will see until it’s too late.

Final Thoughts

Frame softening doesn’t announce itself on day one. It sneaks in over time through a combination of poor settings, excess heat, and overlooked materials science.

Dial in your settings. Know your materials. Use the right gear. And when in doubt, double-check those heat-affected zones. Because once a frame goes soft, there’s no quick fix.

Take your time, do it right, and build something that lasts. Welding is a responsibility, especially when you’re holding the frame together.