Share Post:

Picture a lumbering giant rumbling along the highway, stuffed with cargo and exuding industrial might. Now replace the roar of diesel with a quiet electric hum and a dash of eco-friendly flair.

Sounds a bit like a sci-fi fantasy, right? Except it’s not fiction—battery-powered big rigs are arriving in freight yards and distribution centers across the globe.

I’ve been around vehicles for decades, from vintage gas guzzlers to sleek sports cars, and I’ve never seen progress roar forward so rapidly.

With that said, today we will discuss powerful electric trucks and figure out how they stack up against the diesel dynasty.

Table of Contents

ToggleKey Highlights

- Electric trucks are approximately 5 times more efficient than diesel trucks at highway speeds and 5 to 7 times more efficient in urban settings.

- Battery-electric trucks emit 63% less greenhouse gases compared to diesel trucks, significantly lowering environmental impact.

Performance Potential

Anybody who’s spent time around old-school rigs knows torque is king. Diesel engines have typically played that role, grunting along with enough low-end muscle to haul mountains of steel or pallets of produce.

Electric trucks are flipping the script. Instant torque from electric motors allows them to tackle hills and accelerate in a way reminiscent of that first rocket-like jolt on a roller coaster. Whether it’s long-distance freight or specialized services like towing for heavy equipment, that torque advantage delivers real value.

Take the Mercedes-Benz eActros 600 as an example. Once series production begins (scheduled for November 2024), it’s designed to travel up to 500 kilometers on one charge while hauling an impressive 22 tonnes.

That’s no pint-sized load. Picture a robust, thick-necked farmhorse chugging across fields without losing steam. Not only does it demonstrate raw hauling capabilities, but it also signals a wave of broader confidence in electrified heavy-duty transport.

Numbers matter in freight operations. Studies and tests have demonstrated significantly higher efficiency improvements for electric heavy-duty trucks over their diesel counterparts.

For instance, a study by the California Air Resources Board (CARB) found that battery-electric trucks and buses are about 3.5 times more efficient than conventional diesel vehicles at highway speeds and 5 to 7 times more efficient in lower-speed, urban driving conditions.

Hauling Power in Real Terms

- Torque and Acceleration: Electric motors deliver peak torque from zero RPM, offering smooth getaways and robust climbing power.

- Energy Efficiency: Reduced energy losses and regenerative braking can significantly improve mileage and operational savings.

- Range Prospects: With 500 kilometers already in sight and continuous R&D in battery packs, distances once deemed impossible are more accessible.

I recall a conversation with an old friend who operates a family trucking business. At first, he snickered at the notion of electric freight haulers, quipping that the day he’d see an electric rig towing 20-plus tonnes up a hill was the day he’d retire.

Fast-forward to present day, and he’s readjusting his entire perspective. The raw data is compelling. Once you climb into the cab and experience that silent thrust, it’s a moment of wonder worthy of a gearhead’s scrapbook.

Economic Matters

Everyone knows trucking is about margins. Fuel expenses, maintenance bills, and overall lifecycle costs can make or break an operation.

Electric trucks aren’t just cutting carbon emissions; they’re poised to save companies money in the not-too-distant future. It’s like discovering a treasure chest in the back of your rig when you’d only expected a handful of coins.

The U.S. Department of Energy projects that zero-emission medium- and heavy-duty trucks will outshine their diesel counterparts in purchase, operating, and maintenance costs by 2035. Achieving that involves a trifecta of advancements:

- Better Battery Tech: Lower kilowatt-hour costs and improved energy density

- Economies of Scale: Wider production leads to price drops for key components

- Reduced Wear and Tear: Fewer moving parts means fewer breakages, less downtime, and lower service costs

Daimler’s eActros 600 already has a big name behind it—Amazon. The e-commerce titan ordered 200 of those behemoths for operations in Germany and the UK, aiming for net-zero carbon emissions by 2040. In doing so, they’re betting on real economic benefits, not just eco-goodwill.

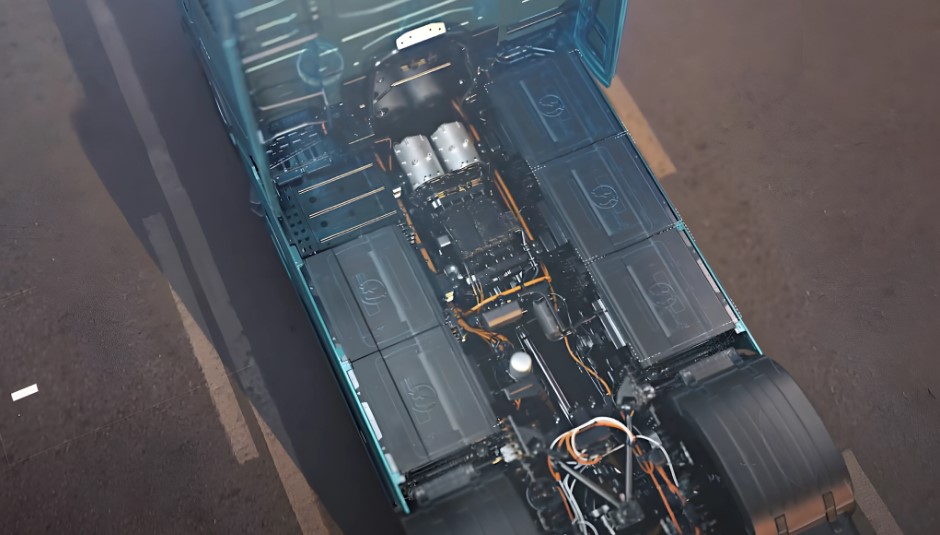

Fuel is replaced by electricity sourced from (hopefully) greener grids, and the expensive labyrinth of pistons, crankshafts, and transmissions shrinks down to an elegantly simpler electric motor setup.

Fleet managers obsess over cents per mile. When battery costs tumble and charging networks expand, the financial argument looks far more appealing. Early adoption can feel like diving into a frosty lake—chilly at first, but thrilling once you realize just how invigorating it can be.

Tech Upgrades

Battery research gallops forward like a thoroughbred on race day. Engineers constantly chase better energy density, safer chemistries, and more efficient production methods. It’s akin to leveling up in a role-playing game: each breakthrough yields a noticeable power boost.

Thermal management advances also hold the key to making sure battery packs stay in their happy temperature zones. Extreme heat or cold can dramatically affect range and longevity, so robust cooling systems protect the hardware while also keeping the driver comfortable.

There’s also a big focus on charging infrastructure. Hauling large loads often involves cross-country routes, meaning dependable, high-speed stations are vital.

Some corridors already feature specialized stations that charge at breakneck speed. Others are exploring hydrogen as a companion technology.

Battery swapping is another concept that could appear, giving drivers the chance to exchange depleted packs for fresh ones in minutes. Imagine rolling into a station, popping out the tired battery pack, and locking in a fully charged replacement—like some futuristic pit stop.

Real-World Triumphs and Tales

I personally believe that the highlights are the prototypes that handle like well-trained stallions: strong, stable, and surprisingly nimble for their size.

Daimler’s eActros 600 is a prime example, with 2,000 orders already lined up. That’s no small sampling of the market; it points to a solid demand from logistics giants.

- Daimler’s eActros 600: Up to 500 km range, 22 tonnes cargo capacity, mass production kicked off in November 2024

- Amazon’s Big Fleet: 200 eActros 600 trucks to serve Germany and the UK, bridging fulfillment centers and stations with minimal noise and zero tailpipe fumes

- DAF 44-Tonne Conversion: Concrete data shows improved efficiency and regenerative braking performance, proving that the shift to electric is more than theory

Summary

Electric trucks are proving more than capable of hauling heavy payloads across varied terrain. Progress in battery tech, robust charging networks, and cost reductions are fuelling major investments by logistics leaders. Engineers merge zero-emission ideals with raw power, forging machines that conquer both city streets and highways.

No one’s claiming the diesel rig is completely obsolete yet. But the day is dawning when quiet, electric might becomes the standard instead of the exception. A future freight fleet of humming heavy haulers is no longer science fiction—it’s turning into an everyday reality on roads worldwide.

Related Posts:

- 20 Cars That Look Like Spaceships - Best Futuristic…

- What to Look for in a Pre-Owned EV? Battery Life,…

- When Will Entry-Level Electric Trucks Hit the Market?

- TRQ Auto Parts - The Truth About Their Quality & Reliability

- How Weather Conditions Affect Electric Vehicle…

- How to Fix Overcharged AC in Cars/Trucks -…